We manufacture individual parts, structural elements or series parts at reasonable prices, with short deadlines and flexibly. Our state-of-the-art machinery and engineering background also guarantee quality production without compromise.

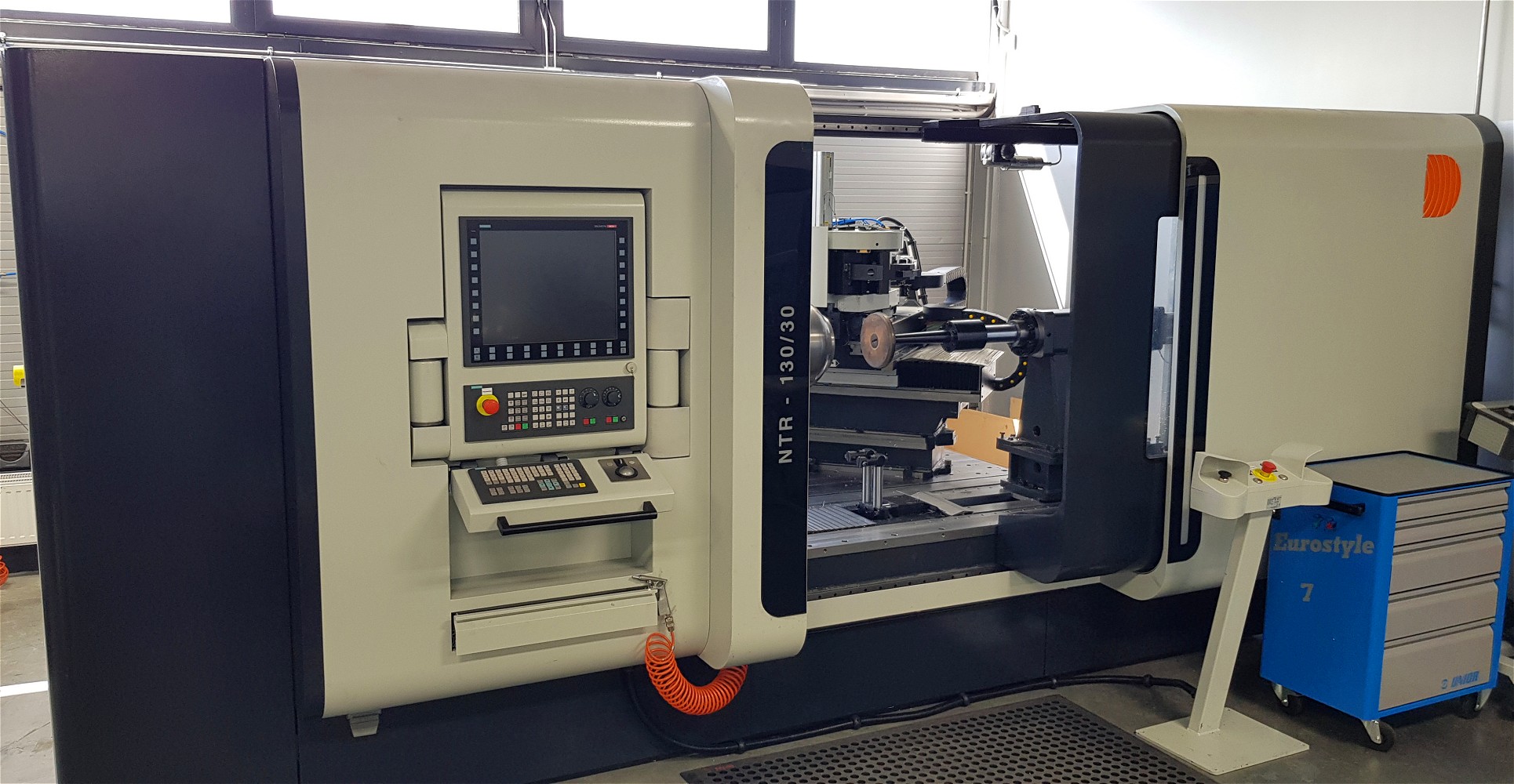

- machining

- plasma cutting

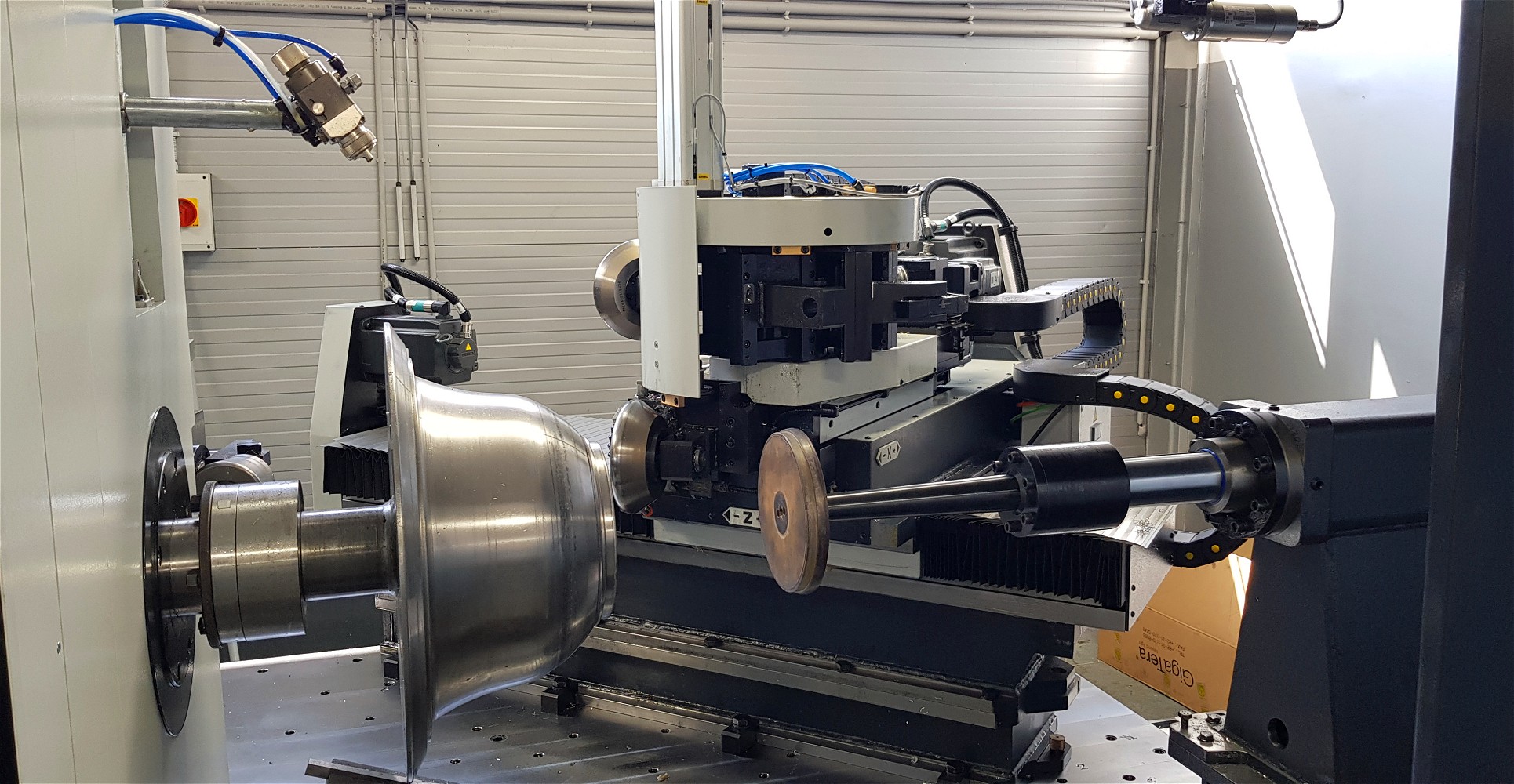

- metal spinning

- cutting

- bending

- welding

- assembly

- surface treatment

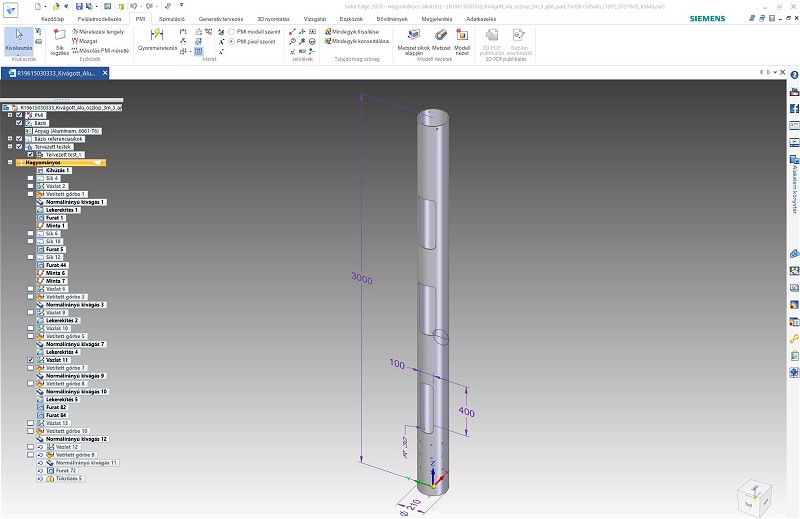

- design with Solid Edge 2D-3D software